Premium Injection Molded Laptop Cases: Precision Craftsmanship Meets Customizable Durability

Hongfei, a leading injection molding manufacturer specializing in laptop protection solutions, is proud to announce the launch of its 2025 Series Customizable Laptop Cases. By combining cutting-edge injection molding technology with sustainable materials, our products deliver unmatched durability, a lightweight design, and personalized aesthetics for global customers.

Key Features & Innovations

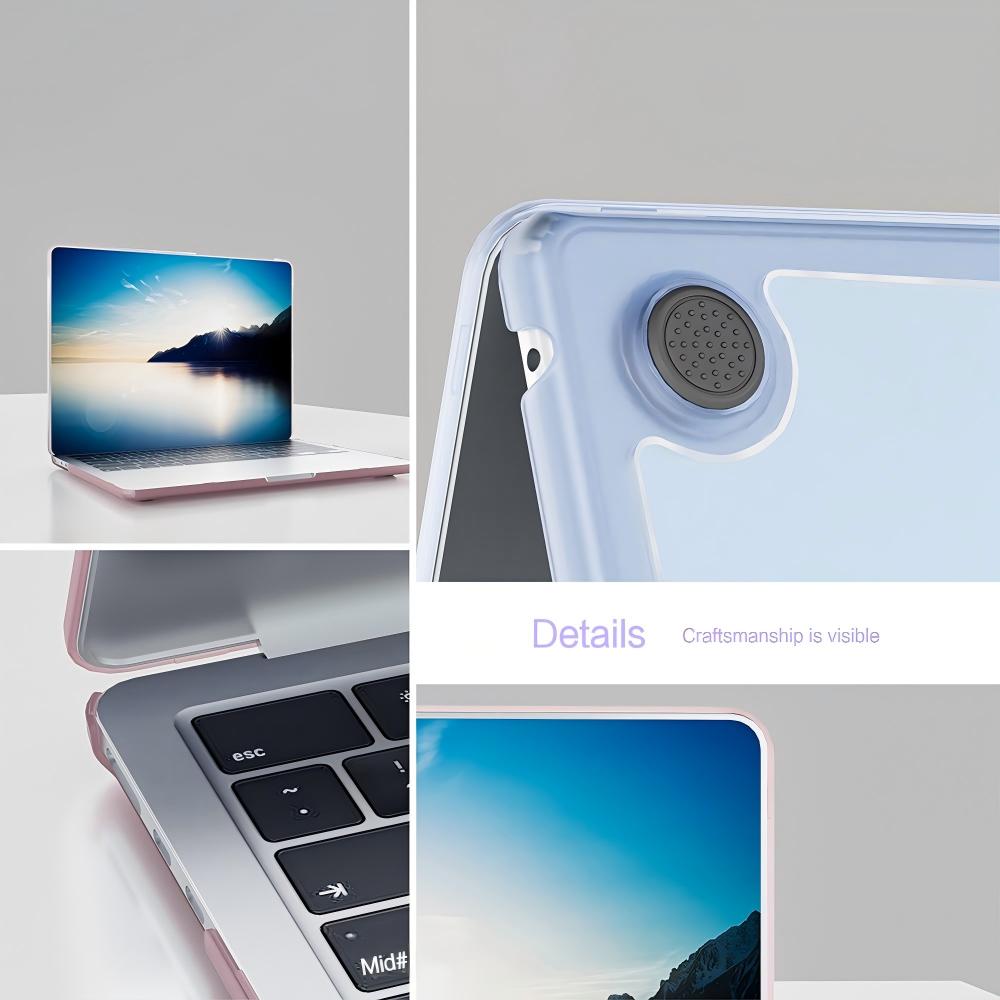

1. Precision Engineering for Optimal Protection

Leveraging CNC-machined molds and multi-stage injection processes, our laptop cases achieve precise wall thickness (0.5–1.2mm) and uniform cooling to prevent warping. Advanced low-pressure injection molding (with pressure stages of 100–130MPa) ensures the seamless integration of reinforced edges and shock-absorbing structures.

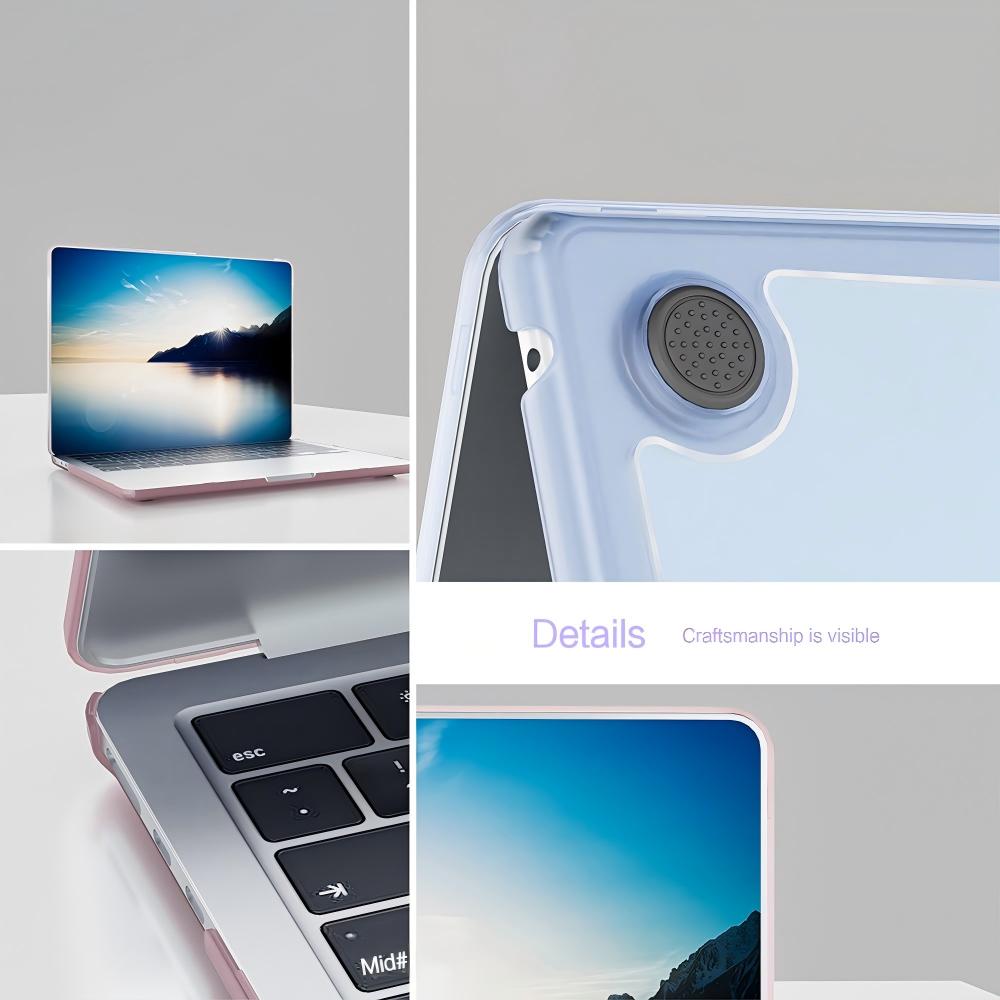

2. Customization & Aesthetic Versatility

In-Mold Decoration (IMD): Logos, patterns, or metallic finishes are directly embedded into transparent PC/PET layers, resulting in scratch-resistant and fade-proof branding.

Material Options: Choose from eco-friendly recycled ABS, military-grade PC+TPU blends, or anti-static carbon fiber composites for your laptop protective case.

3. Sustainability & Certifications

All materials used in our laptop cases comply with RoHS and REACH standards, and select product lines contain 30% recyclable content. Our ISO 9001-certified facilities minimize waste through AI-driven mold optimization and closed-loop cooling systems.

Technical Highlights

Mold Lifespan: Hardened steel molds and automated maintenance protocols ensure a lifespan of 500,000+ cycles.

Turnkey Service: From 3D prototyping to mass production, we offer lead times of 15–30 days for orders exceeding 10,000 units.

Take action

Explore our 2025 product catalog or request a free sample to experience industry-leading laptop cases. For OEM/ODM consultations, please send an email to hf018@szhongfei.com.