The Role and Impact of Robotic Arms in Injection Molding Production

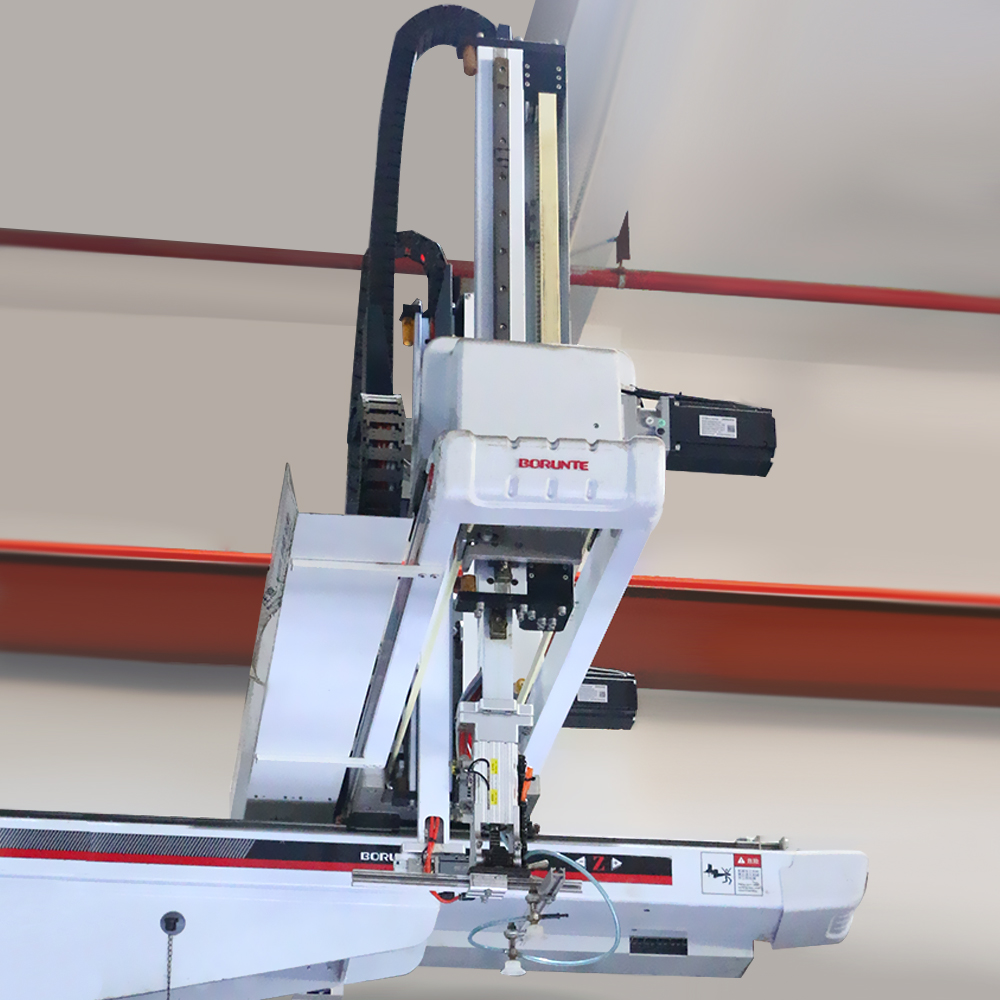

In the dynamic landscape of modern manufacturing, injection molding has become a cornerstone for producing a wide range of plastic components across industries—from consumer electronics to automotive parts. At the core of the transformation in injection molding lies the integration of robotic arms, which have revolutionized traditional manufacturing processes. These automated systems bring numerous benefits, reshaping the industry’s efficiency, quality, and sustainability.

1. Boosting Production Efficiency

One of the most significant contributions of robotic arms to injection molding is enhanced production efficiency. Take HONGFEI, a leading manufacturer, as an example. In the production of laptop and tablet cases via injection molding, traditional processes relied heavily on manual labor for part removal, trimming, and assembly. Robotic arms, however, can operate continuously without fatigue, drastically reducing cycle times. For instance, a robotic arm can precisely extract a molded laptop or tablet case from the injection mold in seconds— a task that would take human operators much longer due to safety checks and manual handling. This speed not only increases per-machine output but also enables manufacturers like HONGFEI to meet tight production schedules and rapidly respond to market demands.

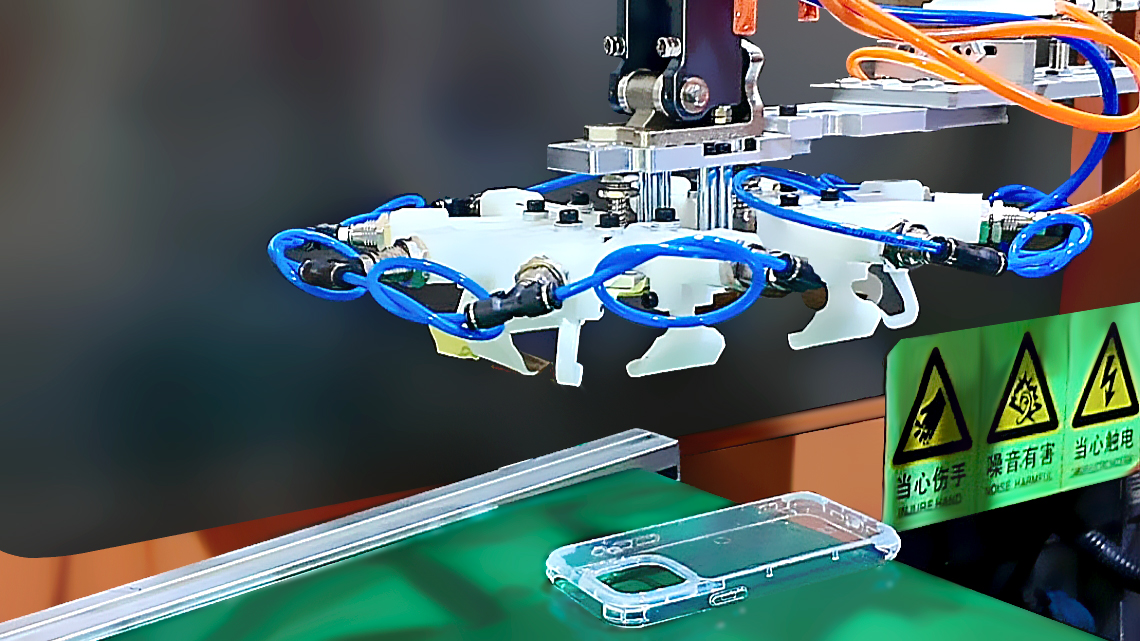

2. Enhancing Precision and Quality Control

Robotic arms excel in improving precision and quality control in injection molding. Programmed with extreme accuracy, they ensure consistent product dimensions and finishes. Unlike human operators, robots are not affected by fatigue, distractions, or skill variations. In HONGFEI’s production of MacBook cases, even the smallest deviation can impact fit and user experience. Robotic arms maintain tolerances within micrometers, guaranteeing each case meets strict quality standards. Additionally, they can be equipped with advanced sensors for real-time quality inspection. For example, vision sensors detect surface defects or dimensional inaccuracies on laptop and tablet cases immediately, enabling prompt corrections and minimizing waste.

3. Improving Workplace Safety

Robotic arms have a crucial impact on workplace safety. Injection molding involves handling hot molds, molten plastics, and heavy machinery, which pose significant risks to human workers. At HONGFEI’s factory, deploying robotic arms to take over these hazardous tasks in laptop and tablet case production eliminates the need for workers to be near dangerous equipment and materials. This reduces workplace accidents such as burns, cuts, or repetitive motion injuries. Moreover, robots can operate in harsh environments—high temperatures or chemically hazardous settings—without performance issues, further safeguarding human health.

4. Enhancing Cost-Effectiveness

While the initial investment in robotic arms is substantial, the long-term savings are remarkable. For HONGFEI, reduced labor costs are a clear advantage, as fewer workers are needed to operate laptop and tablet case production lines. Additionally, enhanced precision and quality control reduce product defects and waste, leading to significant raw material savings. For example, if HONGFEI previously had a 10% defect rate in a batch of 10,000 laptop cases (resulting in 1,000 wasted units), robotic arms could lower this rate to 1% or less, saving substantial materials and production resources. Furthermore, robots’ consistent performance minimizes machine downtime for maintenance, as they cause less wear and tear on injection molding equipment compared to inconsistent manual operations.

5. Enabling Flexible Manufacturing

Robotic arms play a key role in enabling flexible manufacturing. They can be quickly reprogrammed to handle different molds, parts, and tasks. At HONGFEI’s factory, this flexibility allows the company to diversify its product offerings without significant retooling costs. For example, the same robotic arm can switch between producing smartphone cases, automotive interior components, and laptop/tablet cases with different requirements. This adaptability is crucial in today’s market, where consumer preferences change rapidly and manufacturers need to respond quickly to new trends.

Conclusion

Robotic arms have become an indispensable asset in injection molding production. Their impact on efficiency, precision, safety, cost-effectiveness, and flexibility has not only improved the competitiveness of individual manufacturers like HONGFEI but also driven the entire injection molding industry toward a more advanced and sustainable future. As technology evolves, robotic arms will become even more intelligent and integrated, further enhancing the capabilities of injection molding production.